Nitrogen gas is used for a wide range of industrial applications, from modified atmosphere packaging for perishable food products, to preventing fire and explosions in chemical plants. However, while nitrogen is all around us, making up 78% of the air we breathe, obtaining a ready supply of the gas can be problematic and expensive.

Parker offers an ideal solution to this requirement with a comprehensive range of cost effective nitrogen gas generation systems that enable users to produce their total demand for nitrogen gas on their premises, under their complete control.

Using the latest technology, Parker designs and manufactures hollow fibre membrane and pressure swing adsorption (PSA) nitrogen gas generators to provide a solution for almost all applications that require nitrogen gas.

A comprehensive range of Nitrogen Gas Generation Systems:

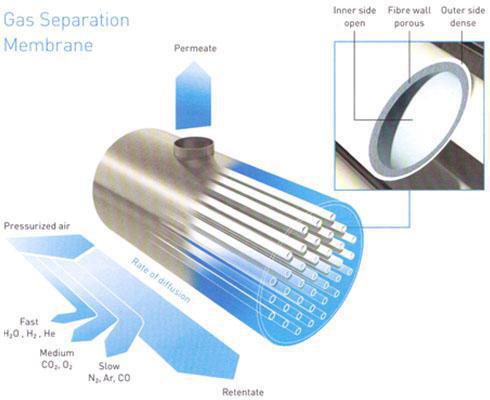

1. Hollow Fibre Membrane

Membrane technology uses bundles of hollow fibres contained within a tube. The fibre walls selectively separate compressed air by diffusing oxygen and other waste gases to the atmosphere while retaining nitrogen and allowing it to pass through the centre of the fibres to the application.

Nitroflow membrane N2 generators

Nitrosource Hifluxx Membrane N2 Generators

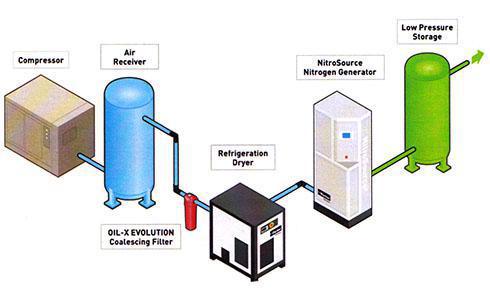

Membrane Typical Installation

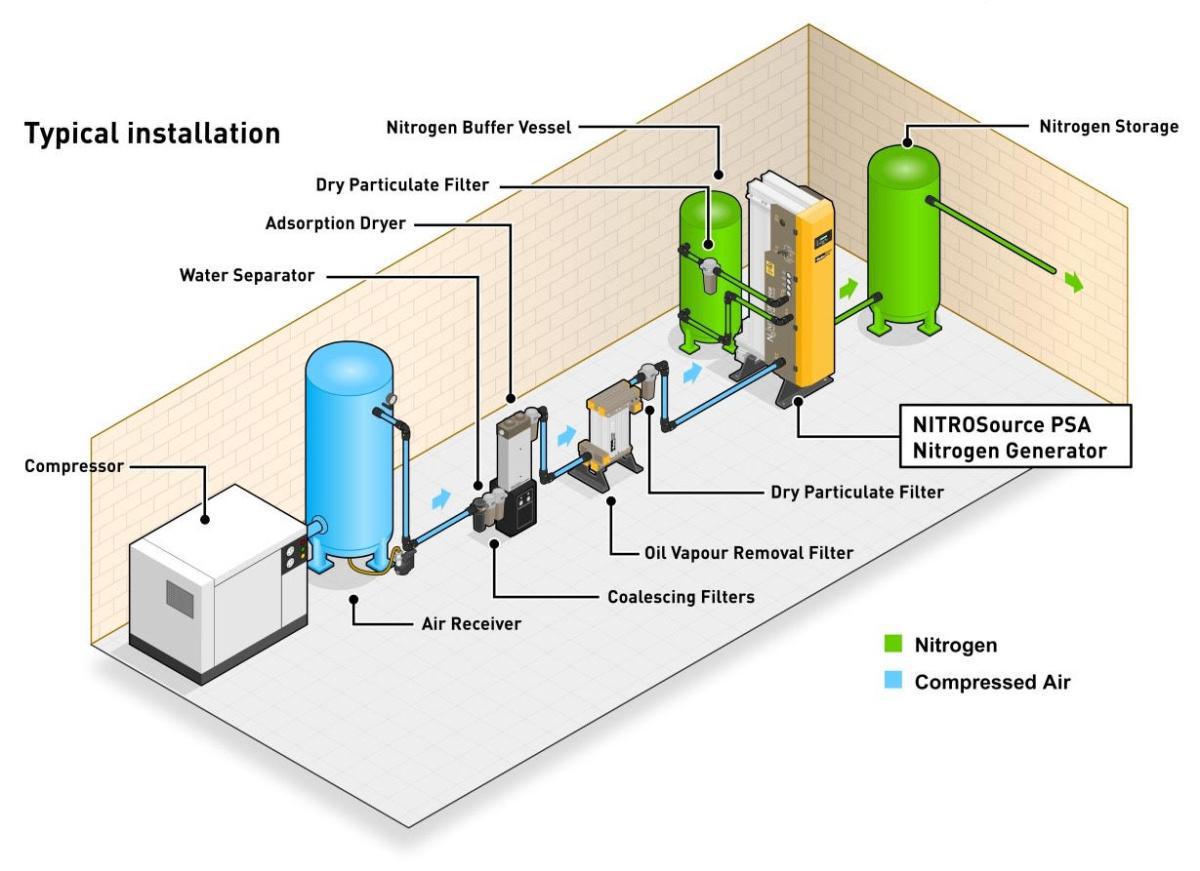

2. Pressure Swing Adsorption (PSA) Technology

Pressure swing adsorption (PSA) technology uses columns of carbon molecular sieve (CMS), to separate compressed air. Oxygen and other waste gases are selectively adsorbed under pressure by the CMS, allowing nitrogen to pass to the application.

Both technologies are designed for use with standard industrial oil lubricated rotary type compressors, using either spare capacity from a central factory air compressor, or from a compressor dedicated to the nitrogen generation system.